Temperature Controllers are a very important part of any electric kiln. At Furnace Engineering we have a comprehensive range of control systems available starting with the most basic and simple to use controller through to micro processor multi ramp multi dwell fully programmable program controllers.

|

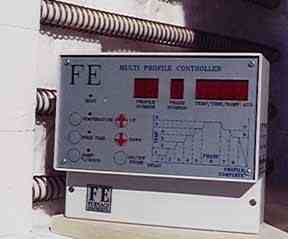

Most temperature controllers are just that and no more , the FE AUTO Multi Profile controller is much more than a temperature controller it is the most advanced KILN controller available today special designed for kiln use. This is a high temperature and low temperature controller with many special safety features build in.

|

|

The FE Auto will stop the kiln from heating in the following situations;

The FE Auto will START your kiln after a power cut and proceed the firing from where it has been interrupted , without loosing the settings in it's memory (this is ideal if you fire overnight and in some locations with unstable power supply).

|

Unlike liquid crystal display's our bright red digits gives a clear view of the kiln temperature even in the darkest locations and shows you if the kiln is ramping or holding and which step and program is processing. |

FEATURES

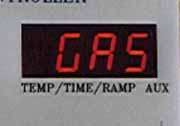

GAS

|

This controller is also suitable for gas kiln use , it will control a two stage burner which gives you a very controlled and even temperature increase. A flame rod could be connected to the controller and as soon the burner flame extinguishes all solenoids will be closed and a alarm beeper will sound to notify you that something is wrong or to red light the burners. A OXY probe could be connected to the controller to measure the oxygen level during the firing which could be displayed in two different ways , in Millie volts and OXY log in which 7 is neutral , all readings above 7 is REDUCTION and below 7 is OXIDATION , this way consistent reduction results can be achieved. |

|

|

|

|

|

|

|

Specifications

|

INPUTS: |

THERMOCOUPLES: |

Type R (Pt/PtRh 13%Rh |

|

|

|

|

Type K (Chromel / Alumel ) |

|

|

|

|

Type N (Nicrosil / Nisil ) |

|

|

|

|

Cold junction compensation for all types |

|

|

|

|

|

|

|

|

FLAME ROD: |

Flame failure protection probe for gas kilns. |

|

|

|

|

Standard response time 5 seconds. |

|

|

|

|

|

|

|

|

OXYGEN PROBE: |

2 or 3 lead types are available , All type using |

|

|

|

|

stabilized zirconia sensor. |

|

|

|

|

|

|

|

|

MAINS INPUT: |

240 Volt AC. max. 10 VA. 50/60 Hz. |

115 Volt AC. optional. |

|

OUTPUTS: |

HEAT: |

ON/OFF with simmer stat action up to 300 C |

|

|

|

Contact rating 240 V; 2 Amp. (relay 1)

|

|

|

ALARM: |

Relay contact to switch alarm horn . (Electric kilns) . For gas kilns this contact switch |

|

|

|

the main gas supply , Flame safety output. Contact rating 240 V ; 2 Amp. (relay 2)

|

|

|

AUXILIARY: |

This output could be switched ON or OFF in each phase. Contact rating 240 V ; 2 Amp. (relay 3) |

|

|

|

|

|

|

12 VOLT: |

12 Volt DC output to operate solid state relays. |

|

|

|

|

|

|

DISPLAY: |

Bright red LED display ,7 digits and 4 single LED's. |

|

FUNCTIONAL |

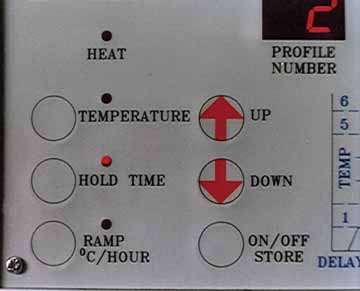

PHASE: |

8 programmable phases or stages with each a ramp; hold time ; max. temperature |

|

SPECIFICATIONS |

|

|

|

|

PROFILES: |

10 user programmable profiles (optional max. 40). |

|

|

|

24 fixed or pre programmed profiles (optional max. 90). |

|

|

|

|

|

|

READ OUT: |

Temperature read out in Centigrade or Fahrenheit. |

|

|

|

Temperature : Resolution +1 degree C or 1 degree F. |

|

|

|

Accuracy + 3 degree C. |

|

|

|

|

|

OXYGEN PROBE |

A: |

Millivolt |

|

DISPLAY |

B: |

Negative Logarithm of oxygen concentration. Display from 00.0 to 99.9. |

|

|

|

(which is more suitable for pottery application). |

|

PROGRAMMABLE |

RAMP: |

Adjustable from 0.1 to 9999 degrees / hour |

|

VALUES |

HOLD TIME: |

Adjustable from 0 to 99 hrs 59 min. |

|

|

TEMPERATURE: |

Adjustable from 0 to 9999 degrees. |

|

|

DELAY TIME: |

Adjustable from 0 to 99 hrs 59 min. |

|

PROTECTION |

Thermocouple burnout & Reverse connection protection. |

|

|

Maximum kiln temperature protection (temperature limit) |

|

|

Temperature stall protection. |

|

|

Auto restart after power failure. |

|

GENERAL |

CASE DIMENSIONS: |

180 mm x 213 mm x 87 mm. |

|

|

WEIGHT: |

1.10 KG. |

|

|

|

|

|

|

|

|

|

|

|

|

Available From.

Furnace Engineering .

Ph (09) 2336690 Fax (09) 2336693

email : kilns@furnace-eng.co.nz

435 Razorback Road R.D.2

Pokeno 1872 New Zealand